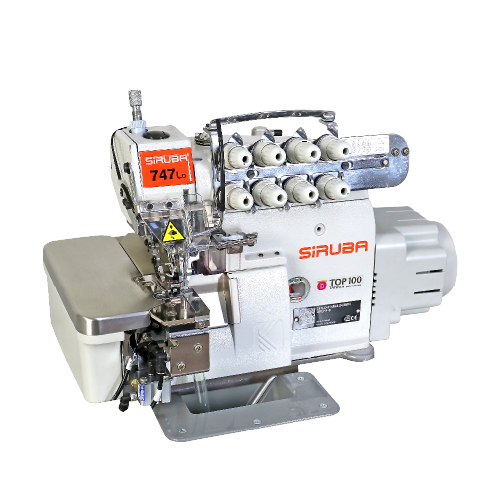

BACK LATCHING SEAMING

-

Buy it now

Buy it now

Choose model

Choose Model

SPECIFICATION

| Specification index | ||

|---|---|---|

| ① Thread numbers | ④ Sewing Fabric/Upper Looper capacity | ⑦ Overedge width |

| ② Model | ⑤ Feed dog type | ⑧ Device |

| ③ Sewing types | ⑥ Needle gauge | ⑨Motor U:U Series H:H Series |

| L7 |

|

|

|

|

|

|

|

|

| |

|---|---|---|---|---|---|---|---|---|---|---|

| Manual | 737L-504M-7-04/BK/(⑨) | 1 | 3 | – | 4 | 0.7-2 | 3.6 | 5 | H / U | 7500 |

| Manual | 747L-514M-7-2⑦/BK/(⑨) | 2 | 4 | 2 | 3,4 | 0.7-2 | 3.6 | 5.5 | H / U | 7500 |

| Manual | 747L-514H-7-2⑦/BK/(⑨) | 2 | 4 | 2 | 4,5 | 0.7-2 | 3.6 | 7 | H / U | 6500 |

| Simplied Fully Auto | 747L-514M-3-24/ECA/BKT/⑨ | 1 | 3 | – | 4 | 0.7-2 | 3.6 | 7 | H / U | 7000 |

| Fully Auto | 737L-504M-3-0⑦/BKF | 1 | 3 | – | 3,4,5 | 0.7-2 | 3.6 | 6 | H / U | 7500 |

| Fully Auto | 747L-514M-3-2⑦/BKF | 2 | 4 | 2 | 3,4 | 0.7-2 | 3.6 | 5.5 | H / U | 7500 |

BACK LATCHING SEAMING

To prevent seam looseness, turn over the thread and then insert into overlock seaming at the beginning of sewing. For sleeve and sideway sewing of underwear, sportswear etc.

Remark 1:

Reduce needle thread’s tension, and adjust

fabric guide to get the special outlook

showing the needle thread on top side.

Remark 2:

Replace upper looper by blind looper LP231

to make 2-thread overlock stitch

| Operation | Code | Description | Applicable Series | Drive Type | |

|---|---|---|---|---|---|

| Manual | BK | Rotary Plate |  | 737L 747L | To equip with servo motor for needle position function is optional and recommended. |

| Simplified Fully Auto | BKT | 1. Simplified type, back latch

length 3cm. 2. With ECA cutter, Needle plate suction channel for thread-end down turning . |  | 747L | 700L; Pneumatic type servo control system |

| Fully Auto | BKF | 1. With VT suction trimmer 2. Multi-operation mode setting 3. Thread-end side turning. Back latch length is adjustable (Min. 1cm) | 737L 747L | BKF; Pneumatic type servo control system | |