LKS-1900AN

LKS1900AN

Computer-Controlled Bartacking Machine

LKS1902AN

Computer-controlled Bartacking Machine (For Belt-Loop Attaching)

LKS1903AN

Computer-controlled Lockstitch Button Sewing Machine

-

Buy it now

Buy it now

| odel name | Bartacking | Belt-loop Attaching | Button Sewing | |||

| LKS-1900AN-SS | LKS-1900AN-HS | LKS-1900AN-FS | LKS-1902AN-SS | LKS-1902AN-HS | LKS-1903AN-SS | |

| Application | Standard | For heavy-weight materials | For foundation | Standard | For heavy-weight materials | Standard |

| Max.sewing speed | 3,200sti/min* | 3,000sti/min* | 2,700sti/min* | |||

| Sewing area | 30mm(L)X40mm(W) | Button size: Round-shaped, flat button Size :Φ8~Φ32mm (standard Φ8~Φ20mm) | ||||

| Stitch Iength | 0.1~10mm(0.1mm step) | |||||

| Needle bar stroke | 41.2mm | 45.7mm | ||||

| Lift of the work clamp foot | Standard 14mm(17mm when the reverse-rotation needle-up function) | MAX. 13mm | ||||

| Auto-lifter | Provided as standard (stepping motor type) | |||||

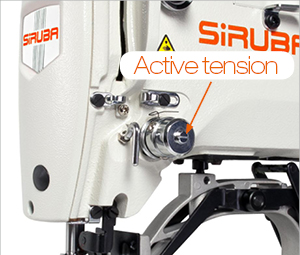

| Needle thread tension | Active tension (electronic thread tension control system) | |||||

| Needle | DPX5(#14) | DPX7(#21) | DPX5(#11) | DPX5(#14) | DPX7(#21) | DPX17(#14) |

| Hook | standard shuttle hook | |||||

| Number of stitches thatcan be stored in memory | Max. 20,000 stitches | |||||

| Number of standard patterns | 50 patterns | 17,18(19,20,21,22*)*This device has been factory-set to”invoking prohibited”status at the time of delivery. | 50 patterns | |||

| Number of data that can be input | 200 patterns (for up to 150 patterns,sewing data can be added.) | |||||

| Enlarging/Reducing facility | 20~200%(1% step), Pattern enlargement/reduction can be done by increasing/ decreasing the stitch length | |||||

| Memory media | EEP-ROM,EP-ROM | |||||

| Bobbin thread counter | Provided as standard(up/down method) | |||||

| Lubrication | Hook: minute-quantity lubrication | |||||

| Lubricating oil | ISO VG32 | |||||

| Sewing machine motor | Compact AC servo motor(direct-drive system) | |||||

| Power consumption | 450VA | 530VA | ||||

| Weight | Machine head (include motor)42kg,Control box 16.5kg | Machine head (include motor)47.3kg,Control box 11.3kg | ||||

FEATURE

Higher productivity

The machine realizes high speed 3,200rpm. In addition to the high speed sewing performance, cycle time can be substantially decreased.

Excellent seam quality

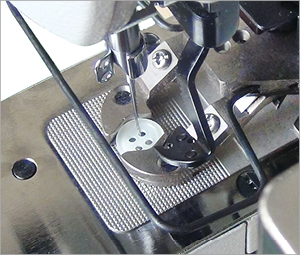

With needle thread nipper, which prevents thread slipping off from the needle hole at the beginning of sewing, and bird-nest problem on the bottom side, and also oil stain problem. For the advanced thread trimming mechanism, the remained thread-end can be shortened.

Wider sewing area and many different sewing patterns

The With 30mm X 40mm (L x W) sewing area, the machine can sew 50 patterns of bartacks, including common shapes, half-moon, round, radical tacking. The machine can sew by the same data of LK-1900 and LK-1900AN (EP-ROM, EEPROM).

Oil stains are eliminated

With dry-head technology, the frame (needle bar, thread take-up) no longer requires oil-lubrication. Just a small quantity of clean oil is supplied from the oil tank to the shuttle hook.

Electronic thread tension controller is standard equipped.

With active tension mechanism, it can set a needle thread tension that matches various sewing conditions (such as thread, material, sewing speed…) on the operation panel, store the data in memory or reuse. The needle thread tension can be separated according to stitching type or portion of a seam, such as the beginning part, base part, zigzag part and ending part (fastening stitch). With operation panel IP-410B, the tension can be set on a stitch-by-stitch basis. This eliminates undesired thread tension variations at a multi-layered part of material or with sewing direction, which upgrades seam quality.

Stepping motor type auto-lifter is standard equipped

Auto-lifter can be set as one-step stroke or double-step stroke, which offers easier sewing material handling. For the double-step stroke, an intermediate stopping height can be set on the operation panel. The presser foot lifter can be set to 17mm Max. by using the reverse-rotation needle-up function in combination with the auto-lifter mechanism.

Excellent workability and operability

The direct-drive head (without belt), which is driven by compact AC servo motor, realizes outstanding responsiveness and improved stop accuracy, which provides a comfortable working condition with low vibration and noise. The arm section is equipped with a hand wheel. Operators can visually check the needle entry points.

The sewing starting point can be corrected.

Auto-lifter can be set as one-step stroke or double-step stroke, which offers easier sewing material handling. For the double-step stroke, an intermediate stopping height can be set on the operation panel. The presser foot lifter can be set to 17mm Max. by using the reverse-rotation needle-up function in combination with the auto-lifter mechanism.The sewing starting point can be shifted in X/Y direction. This enables the correction of a sewing pattern in accordance with the presser foot configuration.

The sewing pattern can be selected by single-key operation

With 6 patterns of linear bartacks. Since the sewing size can be easily changed, the optimal number of stitches and sewing size can be speedily selected according to the belt-loop width.

Operability-oriented design

With its broadly curved feed bracket (presser arm), the machine provides easy placing of sewing material. The slim shape bed and head design makes free space under the arm demonstrates greater operability in handling sewing materials, which increases production efficiency.

Higher productivity, many sewing patterns.

The machine achieves sewing speed as 2,700rpm Max. with quick starting and stopping. Providing 50 sewing patterns, which changeover is easy to be set. With optionally equipping ABF autobutton feeder, LKS-1903AN can reach the highest production efficiency.