PS Series

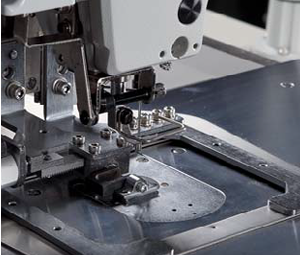

Direct-drive Programmable Electronic Pattern Sewing Machine

| Specification | 1010A-01S | 1310A-01S | 1510A-01S | 2210A-01A | 2516A-01A | 3020A-01A | 3525A-01A | 4030A-01A | 6040A-01A |

|---|---|---|---|---|---|---|---|---|---|

| 1010A-01A | 1310A-01A | 1510A-01A | 2210A-01A/KX | 3020A-01A/HM | |||||

| 1010A-01A/SS | 2210AL-01A | 3020A-01A/MY | |||||||

| Stitch Type | Single Needle Lockstitch | ||||||||

| Max. Sewing Speed | 2800 SPM | ||||||||

| Sewing area (X x Y) | 100 X 100 | 130 X 100 | 150 X 100 | 220 X 100 | 250 X 160 | 300 X 200 | 350 X 250 | 400 X 300 | 600 X 400 |

| Feeding | Intermittent Feeding (Pulse motor drive mode) | ||||||||

| Stitch length | 0.05~12.7 mm | ||||||||

| Max. stitch | 20,000 stitch / pattern | ||||||||

| Work Clamp Drive | S: Pulse motor drives A: Pneumatic drive | Pneumatic drive | |||||||

| Work Clamp Lift Amount | S: Max. 25mm A: Max. 30 mm | Max. 30 mm | |||||||

| 2-step work clamp | S: Integrated-type A: Separate-type | Separate-type | Integratedtype | ||||||

| Stepping Presser foot Height | 22 mm | ||||||||

| Stepping Presser foot Stroke | 0 or 2~10mm (Default setting 3mm) | ||||||||

| Hook | Double Capacity Shuttle Hook | ||||||||

| Thread Wiper | Standard | ||||||||

| Thread Trimmer | Standard | ||||||||

| Digital Tension | Standard | ||||||||

| Thread Breakage Detector | Standard | ||||||||

| External Data storage | Inputted by USB Port | ||||||||

| Motor | Direct-drive AC Servo Motor 750W | ||||||||

| Power | Single Phase 220V, 3-Phase 380V | ||||||||

| Weight | Machine Head: 88 kg, Control Box: 14~16kg | Machine Head: 166 kg, Control Box: 14~16kg | Machine Head: 174 kg, Control Box: 14~16kg | Machine Head: 184 kg, Control Box: 14~16kg | Machine Head: 224 kg, Control Box: 14~16kg |

||||

| Air Pressure/ Consumption | 0.5MPa 1.7L /min | ||||||||

PS-1010A-01S

PS-1010A-01A

PS-1010A-01A/SS

PS-1310A-01S

PS-1310A-01A

PS-1510A-01S

PS-1510A-01A

PS-2210A-01A

PS-2516A-01A

PS-2210AL-01A

PS-3020A-01A

PS-3020A-01A/HM

PS-3020A-01A/MY

PS-3525A-01A

PS-4030A-01A

PS-6040A-01A

FEATURES

New Generation Servo-stepping driving technology

The motor runs more accurately, and the response speed is faster. The temperature rises lower under long working conditions.

High quality direct-drive servo motor

As the maximum speed reaches 2800 rpm so the production efficiency is more improved. The start / stop response is rapid, which is 19% shorter than the conventional type. Low power consumption makes it economy and practical, which is 50% lower than the conventional type.

The min. resolution 0.05mm realizes perfect sewing quality.

With a high resolution of 0.05 per pulse, PS series can make a smooth curve, and a simple embroidery pattern. Even a thick fabric embroidery is available, which is difficult for a typical embroidery machine.

Thread breaking sensor is standard equipped

When it happened thread breaking, the machine senses the problem and then stop with alarm.

Digital thread gripper is optional

Adjusting the upper thread tension with human feeling is the old way. With the digital thread nipper can be set easily to realize the stable sewing quality.

Sewing material setting is easy and accurate

Motor-drive type presser foot (S type) can be set the stroke as 1-step or 2-step.

Stable and uniform seam tightness

Under low tension condition, the seam tightness can be stabilized. Because the height of the intermediate presser can be changed, even if the thickness of the fabric changes as a step, the proper pressure can be maintained to ensure a uniform and stable seam tightness.

Built-in WIFI function for easy connection to production management

system and sewing data real-time transmission.

Multi-data input with 1 SD card slot and 2 USB ports.

NS600 pattern editing software

Easy pattern editing by computer. VDT, SEW, and the other format compatible.

⋅ Pattern editing panel with instruction for easy creating your sewing patterns.

⋅ Compact sewing data tuning area for quick modification.

⋅ Function selection area with graphical display for user friendly.

⋅ Intuitive display of sewing data without changing the page.

⋅ Input and output easily.

⋅ Intuitive display of sewing data without changing the page.

⋅ Input and output easily.

DEVICE

MY

Cap brim

HM

Template fast changing

KX

Pocket welting

SS

Side shift clamp

FZ

Inverted Clamp