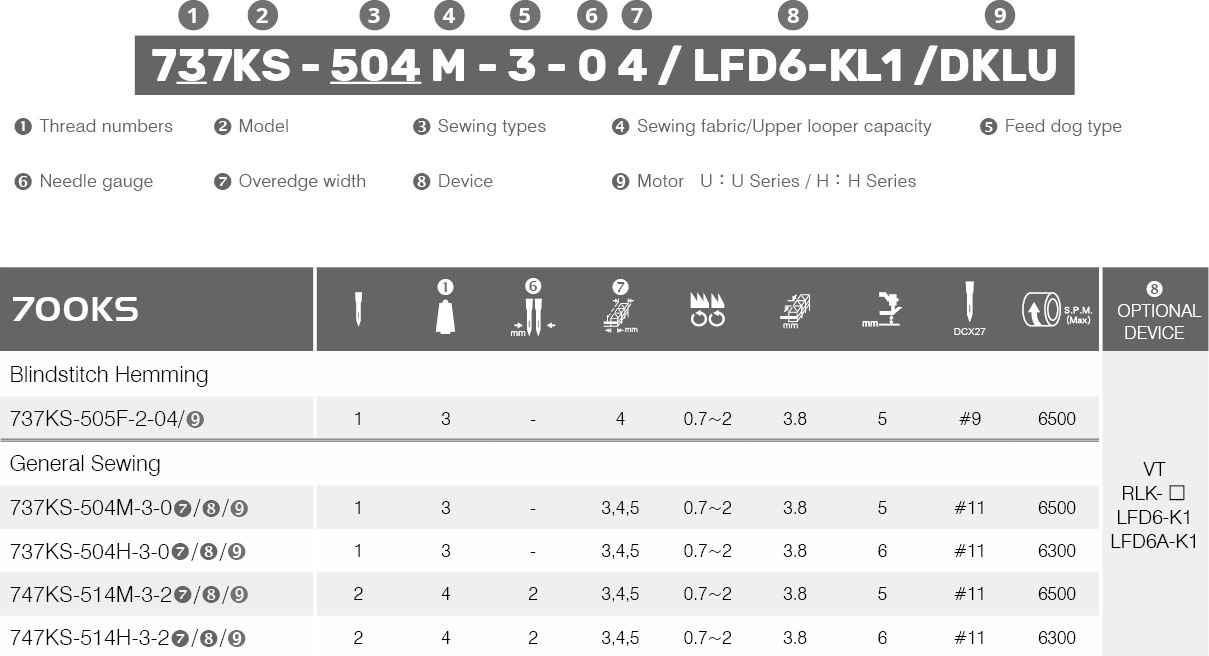

Features

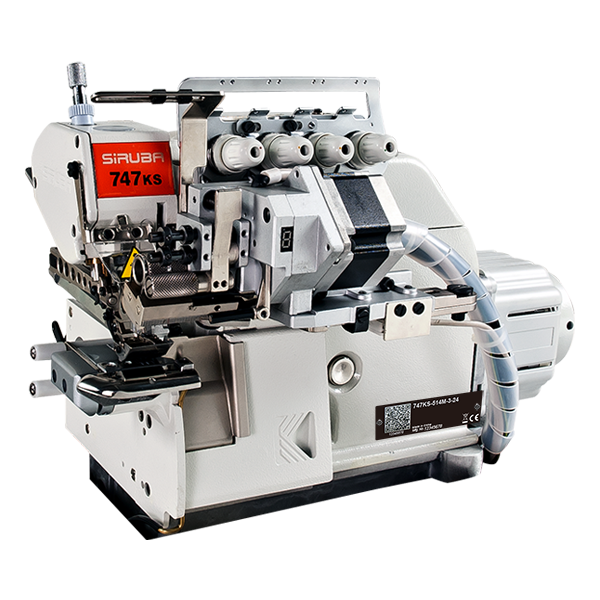

Succeeding 700K Series’ features, we develop cylinder bed mechanism to extend to 700KS Series.

‧ Cylinder Bed Circumference: 148mm

‧ Stitch Length Adjustment: Push-button

‧ Differential Feed Ratio Adjustment: Lever type

‧ Lubrication: Fully-automatic

Exclusive optional device

LFD6-K1 & LFD6A-K1

Multi-function computerized automatic elastic attaching (700KS Applicable)

For attaching elastic tape on small openings of swimsuit, leotards or brief, etc.

By computer control, with auto cutting and auto tape feeding, elastic tape sewing can be done by multi-section tension and length.

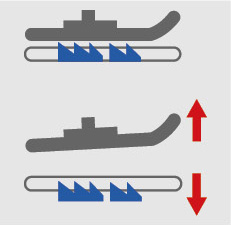

Feed dog dropping function :

when presser foot lifts, the feed dog drops to ensure tape feeding without

obstacle.

Direct drive servo motor :

Electrics highly integration realizes the accurate series movements.

TAPE FEEDING / CUTTING

‧3 operation modes: Auto, Manual, and Test. Auto/ Manual section changing with LED indicate lamp.

‧Precise feeding and the length setting unit is mm.

‧Adjustable feeding of forward, delay, reverse, and forward feeding with reverse function.

‧Speed compensation with 10 default values for choice.

‧For different sewing situations, active feeding may be applied by forward/ reverse when sewing. If sewing operation failed, auto/ manual return to the first section of sewing program.

‧Air blow tape feeding function.

SETTING / MEMORY

‧Memory of sewing program set: 10 sets

‧Program section: 18 sections.

‧LCD panel shows setting status, operation mode, and error code.

‧Touch panel : Graphical user interface is easy for setting. New added testing mode is easy for beginner.

ADDITIONAL FUNCTION

‧Thread releasing

‧Suction thread chain cutters energy saving: Starting/ Ending air suction’s time is adjustable.(by stitch counting)

‧Auto presser foot lifting by paddle step-back.

| LFD6-K1 & LFD6A-K1 SPECIFICATION | |

| Program set memory | 10 sets |

| Sections of every program | 18 sections |

| Tape feeding length per stitch | 0.2mm~6.5mm |

| Max. Speed (stitch length 5mm) | 4200 R.P.M |

| Tape feeding motor | 5-phase stepping motor |

| Voltage | AC 110~220 V |

DEVICE

*Standard devices are not mentioned in model name.

| Code | Description | Remark |

| LFD6-A | Short roller: for tape width 16 mm below | LFD6-K1 Standard |

| LFD6-AA | Long roller: for tape width range 16mm~50mm | LFD6A-K1 Standard |

| LFA | Electric tape feeding device Voltage, 110V(Part NO.LFA-1A) / 220V(Part NO.LFA-2A) |

Optional |

| LF290 | Euntangling wheel Voltage, 110V(Part NO.LF290-A1) / 220V(Part NO.LF290-A2) |

Optional |

| VT * | Vertical Pneumatic chain cutter | Standard |

| TU* | Dust collector suction device | Standard |

Tubular Extending Roller set

‧Diagonal extending roller with closed table top

Tubular Extending Roller set

‧Diagonal extending roller with open table top

Tubular Extending Roller set

‧Three point extending roller with open table top

Tubular Extending Roller set (pneumatic)

‧Three point extending roller with open table top

‧Recommend Package : TUA-38S(ST) / DKH201ADE-A/ 700KS-T3-P