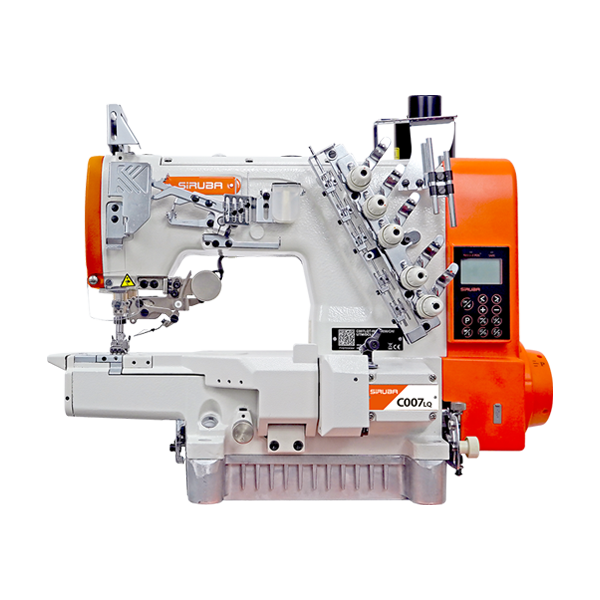

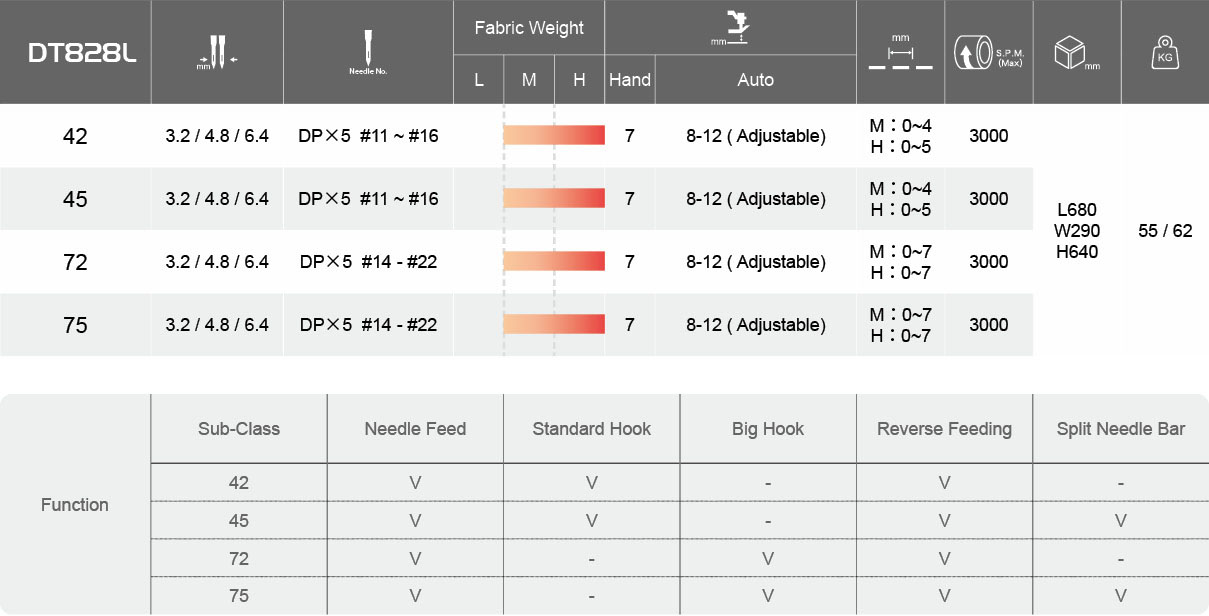

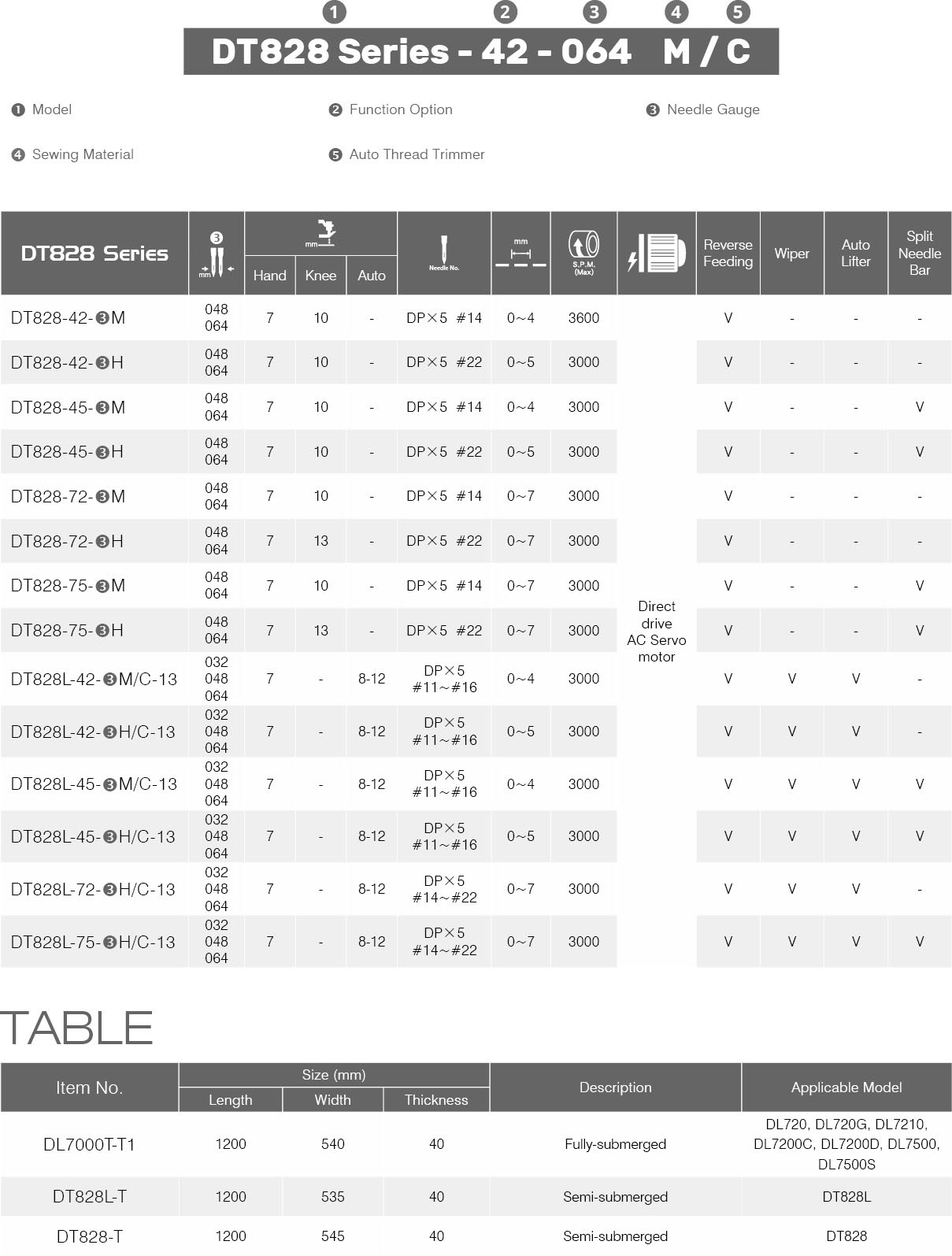

DT828L

Computerized Double Needle Lockstitch Machine with Double Stepping Motor

- Stepping motor bidirectional driven technology (patent) :

One step motor control trimming and pressing foot lifter work.

The unique thread trimmer device:

Adopt step motor to drive,stable, light noise and convenience on maintenance. - Straight knife system :

Straight knife thread trimming mechanism, stable thread trimming. - Sealed oil tank design:

Effectively avoid the material dirty from oil. - Multi-function key operation panel:

The operation box has direct key content, and the operation is simple and rapid.

The multifunctional buttons:

easy to achieve angle change, reverse stitch, seam stitch and stitch compensation.

High-quality reinforcement stitches:

Step motor can accurately control the feeding, making reinforcement available for any stitch length.

Electronic knee pad:

Without worker changing oper-atinghabits,presser foot can be easily lifted.