ASP-EBJ Series

Automatic Elastic Ring Making Machine

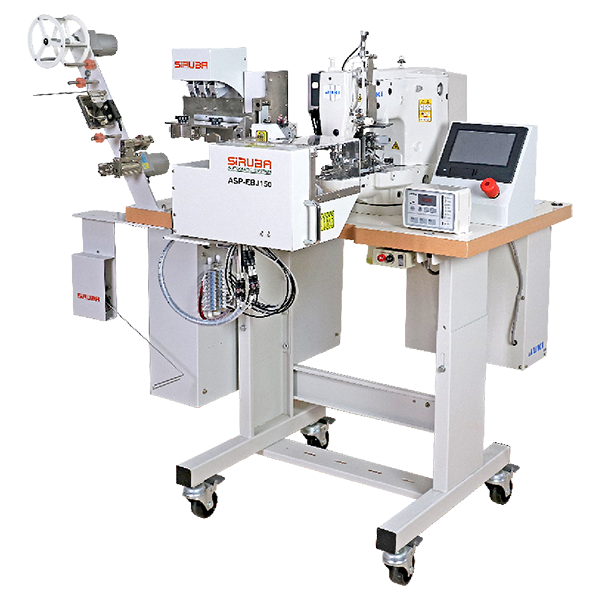

| Model | ASP-EBJ100A | ASP-EBJ100S | ASP-EBJ150 | ASP-EBJ200 |

| Machine Head | JUKI LK-1920 | JUKI AMS210ENSS | ||

| Sewing Speed | 2500 SPM (Max ) | 2800 SPM (Max ) | ||

| Needle Type | DP×5 #14 | DP×17 #14 | ||

| Stitch type | Single Needle Lockstitch #301 | |||

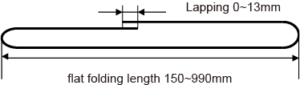

| Rubber Width | 20~50 mm | 6~20 mm | 20~50 mm | 20~90 mm |

| Pattern Memory | EEPROM | IP-420 (JUKI AMS) | ||

| Max. Numbers of Pattern | 99 Patterns | 999 Patterns | ||

| Tape Cutting Method | Knife Cutting | ◎ Knife Cutting △ Ultrasonic Cutting |

||

| Production Capacity | Depends on the stitch pattern, Ex: 190 stitches pattern, Cycle Time: 8 Sec./ pcs (Max.); 3600 pcs/ 8Hr |

Depends on the stitch pattern, Ex: 71 stitches pattern Cycle Time: 6 Sec./ pcs(Max.); 4800 pcs/ 8Hr |

Depends on the stitch pattern Ex: 190 stitches pattern as below Cycle Time: 8 Sec./ pcs(Max.); 3600 pcs/ 8Hr |

|

| Stitch Length |  |

|||

| Air Consumption | 30 L/Min. | |||

| Air Pressure | 0.5 MPa | |||

| Power Supply | Single Phase 1Φ AC200~240V 50/60Hz | |||

| Power consumption | 750 W ( Max ) | 750 W ( Max ) | 800 W ( Max ) | 800 W ( Max ) |

| Dimensions | (W)1230X(D)1030X(H)1530mm ( With table and thread stand ) |

(W)1550X(D)1150X(H)1530mm (With table and thread stand ) |

||

| Optional Device | ||||

| Stacker | △ | △ | △ | △ |

| Pre-Ironing | ― | ― | △ | △ |

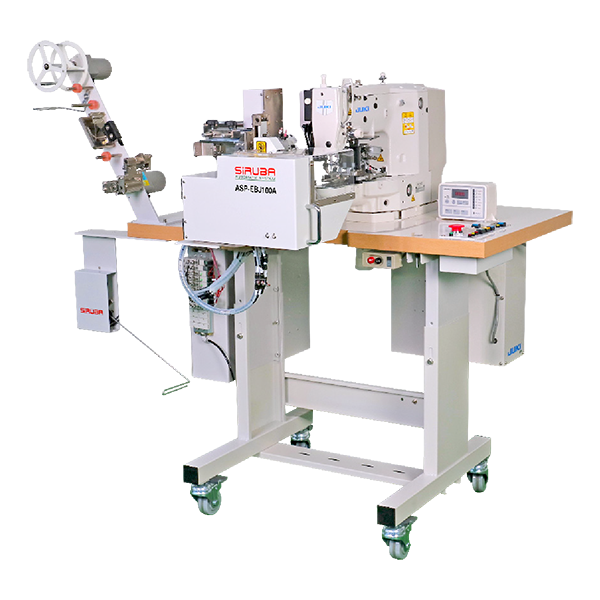

| LOGO Identification | ― | ― | ◎ | ◎ |

◎Standard △Option

Features

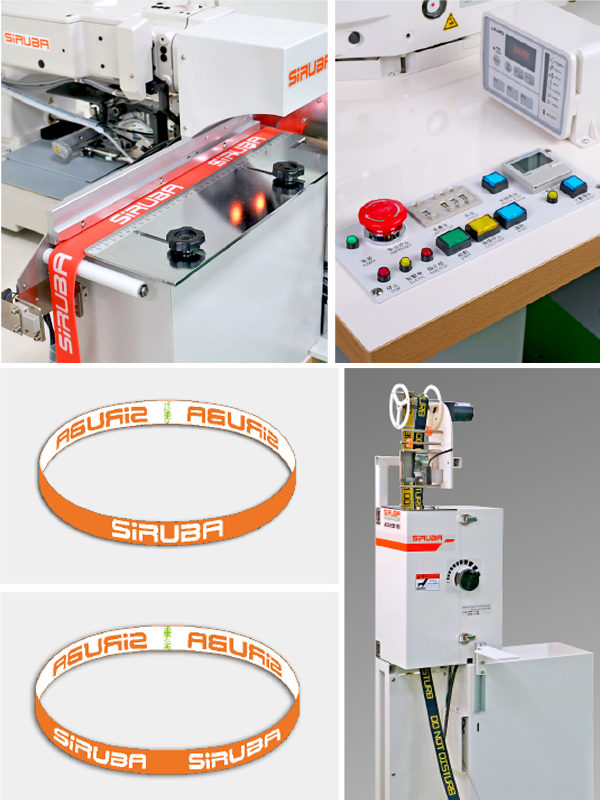

1.EBJ Series realizes automatic sewing of elastic band. Measuring, cutting, feeding, and sewing are in sequence with absolute stability. It is accurate and reliable.

2.Unmanned Production with high yield rate. Payback period is short as maximum 1-year ROI.

3.By high-end sensors, it detects the feeding sensitively with real-time alarm and auto pause function.

4.Pre-ironing device is optional, which ensures the flatness when the material is entering, to solve the problem of wrinkles or twists.

5.Visual identification system is optional, which detects Logo and then positions cutting and sewing according to user’s setting.