Climate Change Management

SiRUBA has implemented an internal control system and internal audit framework. Additionally, we have formulated policies and processes of ESG risk management, and risk management encompassing sustainable operation, environmental factors, societal considerations and governance standards. Given the increasing significance of energy, climate change, and extreme weather conditions due to global warming, we have established a Task Force on Climate-related Financial Disclosures (TCFD) framework. This framework is designed to address the impact of climate change on our operations. The TCFD framework is structured around governance, strategy, risk management, indices and targets. Each member of the Sustainable Development Committee is responsible for identifying climate-related risks and opportunities. Subsequently, they develop strategies to address these factors, incorporating recommendations from external consultants. The committee regularly reports to the Board of Directors on an annual basis, ensuring effective implementation and monitoring of the outlined strategies.

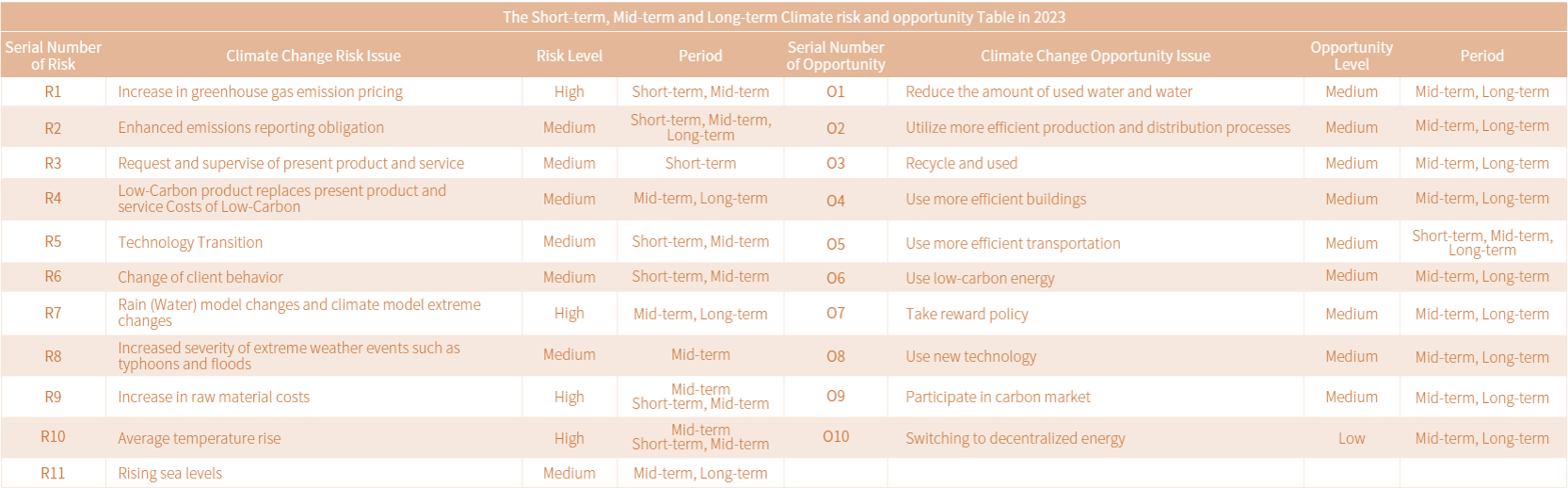

Note 1: Short-term: 1-3 years, Medium-term: 3-5 years, Long-term: years

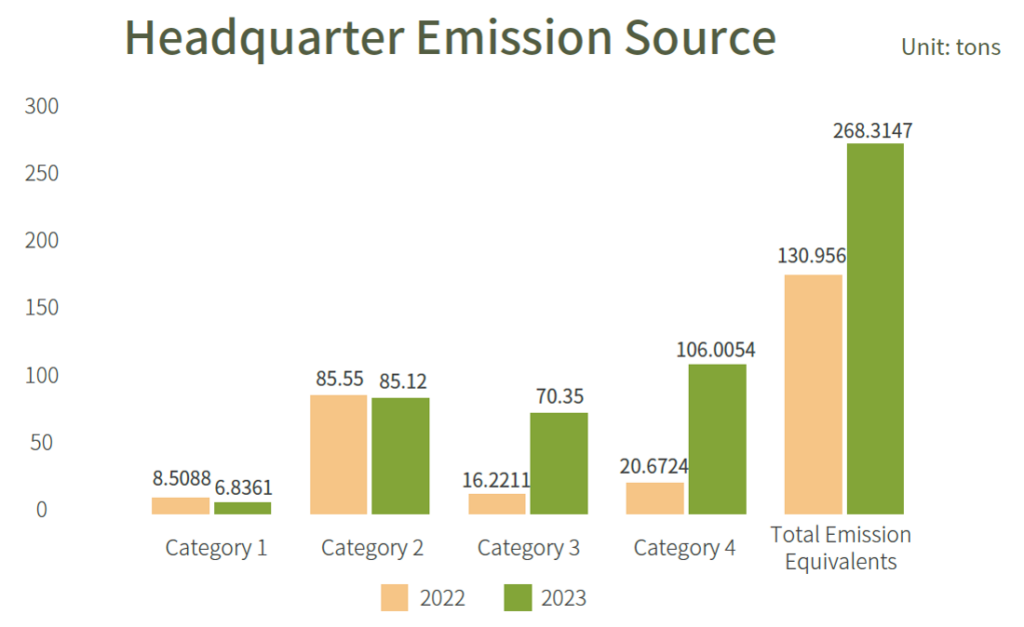

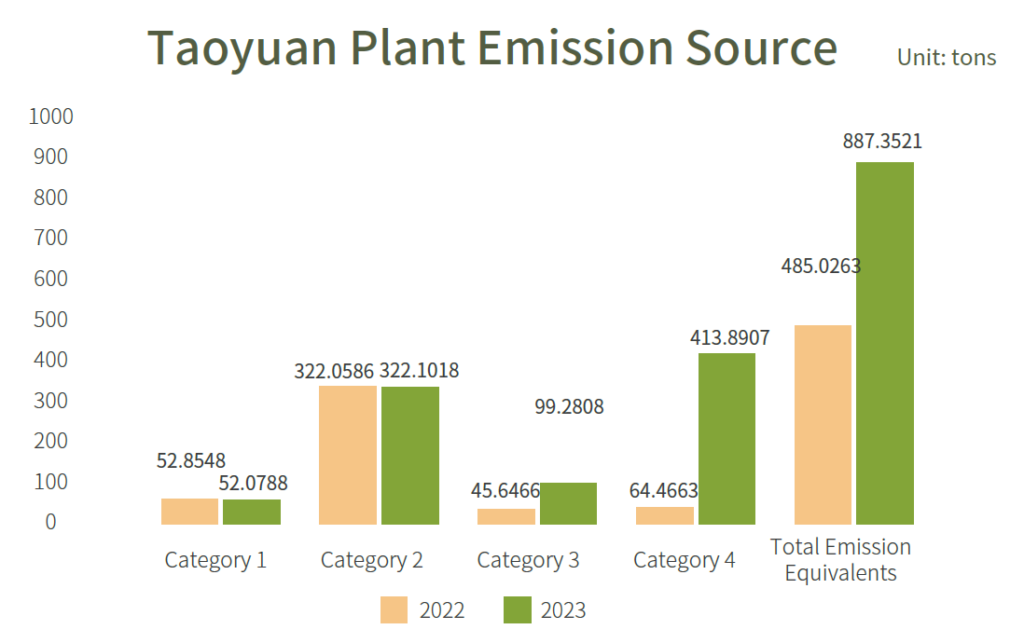

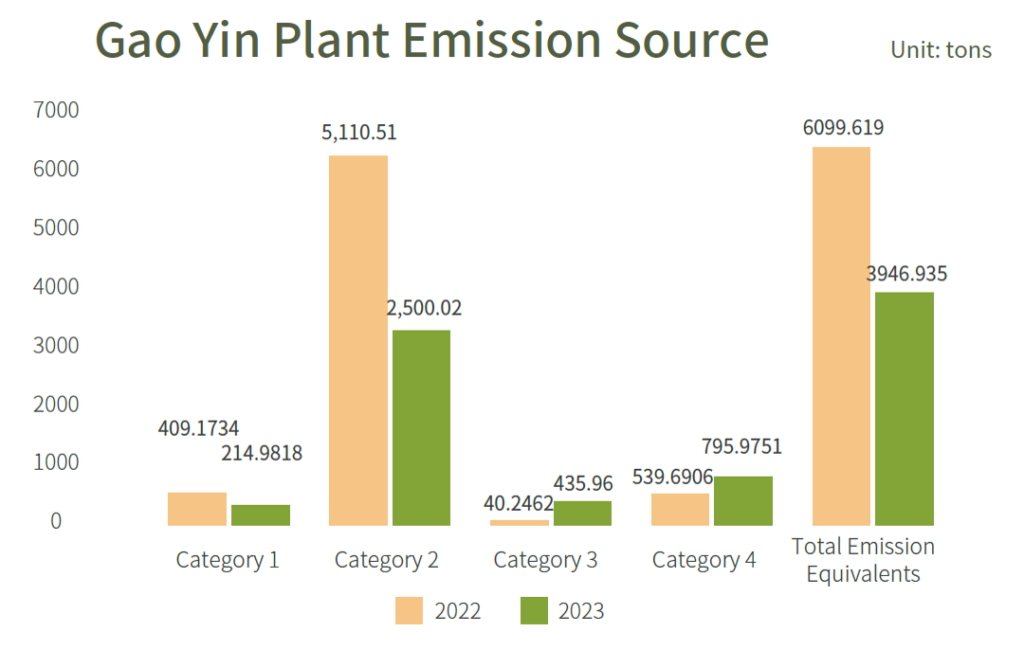

GHG Emission

Affected by global warming in recent years, there has been ozone depletion and increasingly extreme climatic conditions. We are committed to collaborating closely with the government on this global issue. Recognizing the influence that enterprises exert on the environment, we have adopted the ISO 14064:2018

standards and requirements for Greenhouse Gas (GHG) inventories. Conducting thorough statistical analyses of inventory outcomes, we aim to provide references for future planning and the execution of improvement initiatives.

The current main emission sources are:

- Direct (Scope 1) greenhouse gas emissions: Category 1

- Energy indirect (Scope 2) greenhouse gas emissions: Category 2

- Other indirect (Scope 3) greenhouse gas emissions: Category 3, Category 4

Energy and Resources Management

Efficient energy usage is imperative for modern enterprises. Energy management assumes a pivotal role in corporate operations and the preservation of ecosystem. To skillfully regulate energy consumption and bolster its efficiency, we have established the «Energy Conservation Management System» as our overarching guideline. In alignment with energy regulations, each plant takes charge of monitoring energy usage. Through the PDCA (Plan-Do-Check-Action) cycle, we verify the effectiveness of implementation is confirmed and continually strive for enhancement. This endeavors to fulfill the company’s aspirations for sustainable development and harmonious coexistence with the environment.

Energy Management

Policy

Continuous Improvement

Continuously enhance energy performance by supporting improved energy design and implementing energy-saving solutions.

Rule Compliance

Adhere to energy laws and regulations, maintaining records and submitting declarations in accordance with relevant energy submitting.

Performance management

Execute energy conservation programs, allocate resources and information to achieve goals and objectives, and eliminate potential energy waste.

Energy efficiency and carbon reduction

Enhance energy techniques, develop green energy solutions, and cultivate the value of energy cycling.

Implementation Method

Energy saving and carbon reduction

- Turn off lights during the lunch break to reduce the energy consumption.

- Maintain office air conditioning temperatures between 26°C and 28°C to lower carbon emission.

- Innovate energy-saving and carbon reduction products.

- Install of solar power generation systems to enhance the renewable energy utilization.

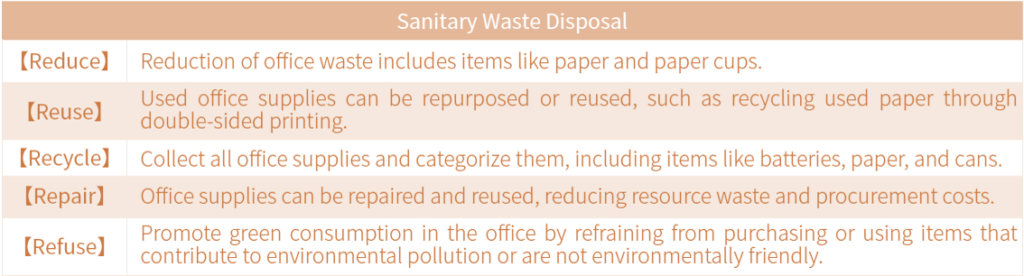

Waste reduction/Garbage classification

- Practice waste separation and utilize recycling bins to achieve waste reduction.

- Cease the use of disposable tableware to minimize domestic waste.

Industrial Waste

Industrial waste is required to comply with regulations, and it is classified into storage categories based on the chemical properties of waste. After classification, the waste is then entrusted to manufacturers approved by the competent authority to perform the cleaning process.

Green Purchasing

- Promise to provide products without Substance of Very High Concern (SVHC) as published by REACH.

- We adhere to the EU RoHS environmental regulations, promote green procurement management, and require suppliers to provide raw materials and process. es that are free from harmful substances.

Green Product

- SiRUBA has established a comprehensive process for controlling restricted environmental substances, which is primarily practiced as follow:

- The manufacturer signs a statement to fully comply with RoHS, REACH international environmental

- regulations and customer requirements.

- Regular review of substance testing reports

- Implementation of audits for supplier green product management.

- There were no violation of green product regulations or customer product requests in 2022.

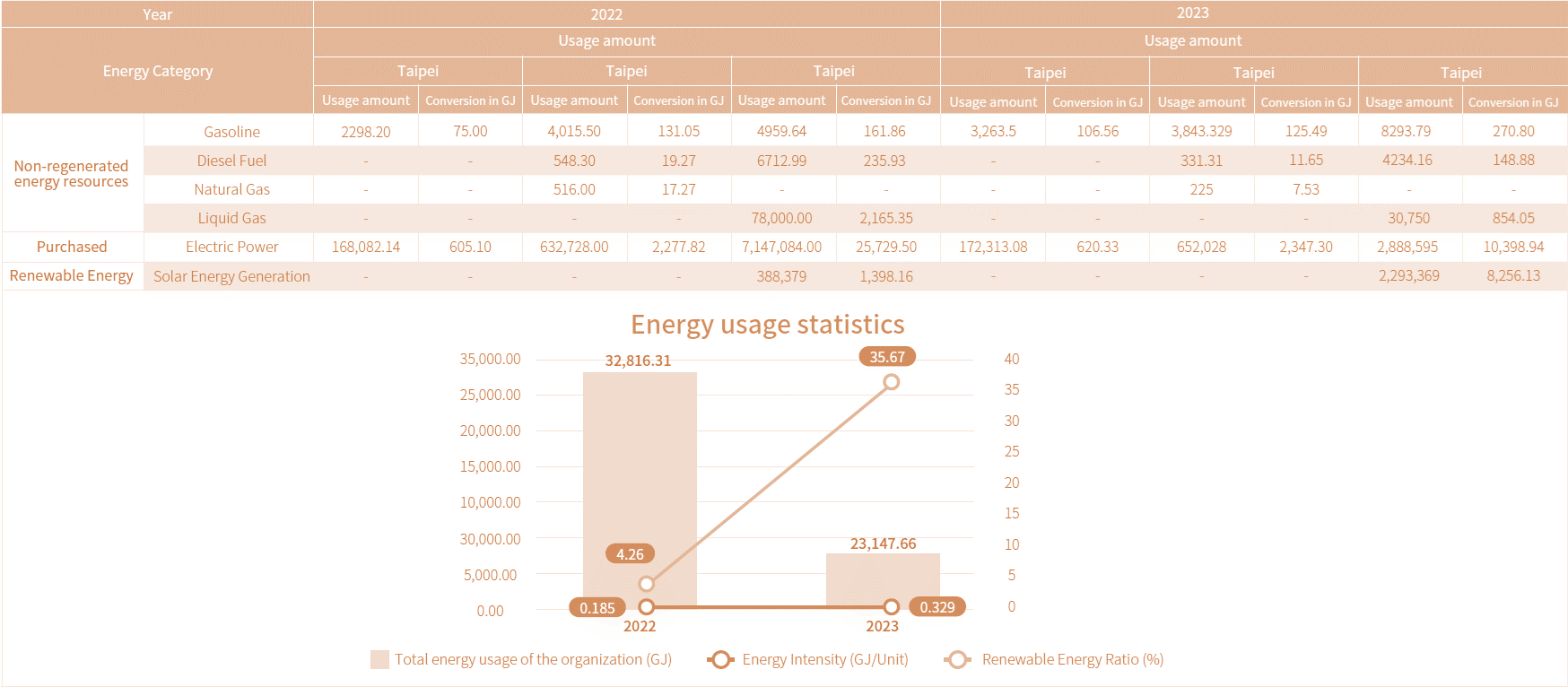

Energy Consumption

Energy usage within the factory primarily encompasses equipment operation, electricity consumption, official vehicles, and stackers. On the other hand, the primary energy consumption at the head office is attributed to electricity.

Note 1: GJ=10°J, 1 kilowatt-hour of electricity is 3.6 million joules, 1 kcal is 4,184 joules; referring to the Taiwan Environmental Protection Agency’s greenhouse gas emission coefficient management table (version 6.0.4), the calorific value of gasoline is 7800 kcal/L, while diesel oil has a calorific value of 8400k cal/L; liquid gas has a calorific value of 6,635 kcal/L, and natural gas has a calorific value of 8,000 kcal/M3

Note 2: The production capacity in 2023 is 59,105 units. The power generation of Gao Yin is 3,678,519 kWh, excluding the feedback grid used.

Effective energy management has become an essential strategy for SiRUBA’s sustainable development. We engage in activities such as inventorying, monitoring and addressing abnormal energy usage. On a monthly basis, the factory reports its electricity consumption during factory meetings and compares it to the same period in the previous year.

Through self-supervision and management, we enhance the energy management mechanism, facilitating the establishment of energy-saving goals and plans for future energy-saving improvement. We integrate the concepts of green low carbon practices into our product development and innovative technique to minimize energy resource consumption. Our product design approach incorporates green design principles, thereby reducing environmental hazards and impacts throughout each stage of the product life cycle.

Renewable Energy

We recognize that achieving the goal of carbon neutrality in 2050 necessitates the utilization of renewable energy as a crucial implementation strategy. Since 2022, our company has been installing solar power generation systems at the Gao Yin Plant. Since its launch in August, the electricity generated in 2023 amounted to 1,3242.67 GJ. Among this total, 8,256.13 GJ were consumed, resulting in a utilization rate of 62.34%. The use of renewable energy accounted for 35.67% of the total energy consumption. To ensure sustainable enterprise operations, the Taoyuan plant devised a solar roof renewable energy generation plan in 2019. The plan involved leasing the roof to the solar photovoltaic industry for the construction of new solar panels, which capture solar heat and convert it into electrical energy. This initiative aligns with governmental efforts to promote green energy and encourage businesses to participate in solar photovoltaic construction projects to address power shortage. The parallel connection of SiRUBA’s solar photovoltaic power generation was established on April 13th, 2021. SiRUBA’s solar power generation planning not only enables wholesale electricity distribution but also significantly diminishes the need for air conditioning in the factory area due to the shading effect of the roof scaffolding. This dual benefits facilitates energy saving and carbon reduction, promising substantial future reductions in electricity costs. The total capacity of SiRUBA’s solar energy installation is 242KW, with an estimated total power generation of 5.809 thousand kWh over 20 years. The anticipated income from wholesale electricity pricing is approximately NT$ 29.21 million, contributing to a reduction of 3.07 million kg in carbon dioxide emissions.

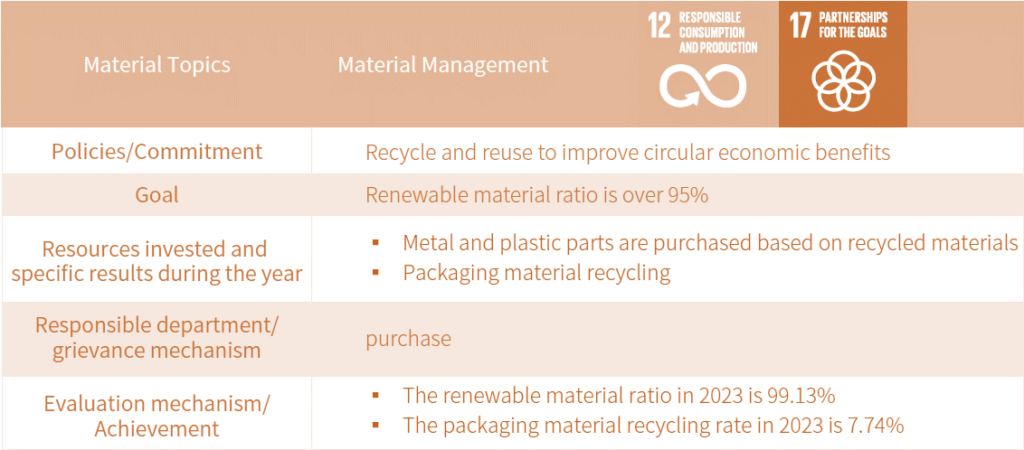

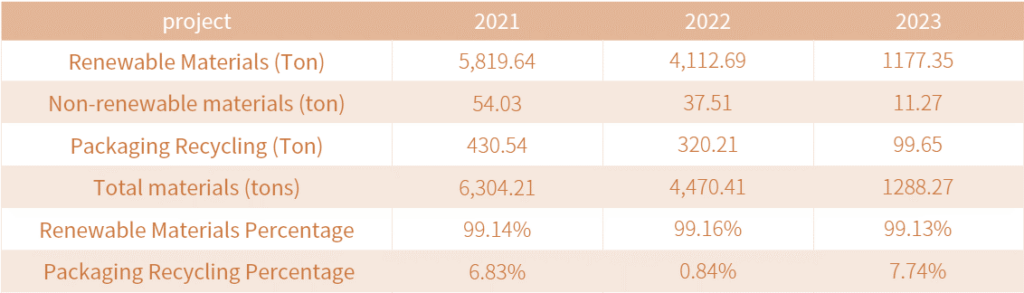

Material Management

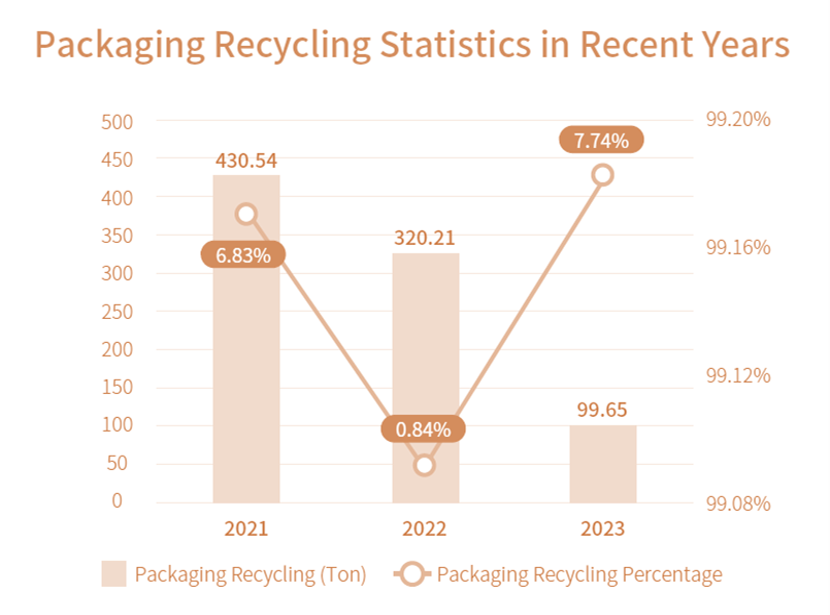

In recent years, the concept of the circular economy has gained momentum, prompting companies to initiate waste reduction efforts. SiRUBA participates in recycling product packaging materials such as paper, styrofoam, plastic bags, and wooden pallets. We also collaborate with suppliers to responsibly recycle and recycle environmentally friendly styrofoam. Furthermore, we implement recycling and reusing practices for process waste, including waste base oil, cutting oil, metal, and cartons. These materials are sent to qualified recycling facilities. Regarding products, the SiRUBA Foundation, the Textile Industry Research Institute, local social welfare organizations and charitable institutions jointly sponsored a series of «Project ReSEW’s» activities. These initiatives involve the development and testing of sewing machines to transform waste fabrics and various textile remnants. Materials such as surplus inventory, defective products, and sample cloth from KAULIN are repurposed through sewing techniques, enhancing the value of regenerated resources. This approach is in alignment with the principles of the circular economy.

Water Resources Management

No water is used in the production process of SiRUBA products, and all water is used for office use. Although it is not a water-intensive industry, considering the increasing shortage of water resources around the world, we actively respond to and implement the «water conservation» policy. In terms of water resources management, we follow relevant environmental laws and regulations to record and report, and conduct measurement and statistics on various water needs, and try to save water and handle it properly. According to the World Resources Institute’s water resources management tool, Taiwan It is an area with medium and low water resources pressure, so it does not draw water from high-pressure areas. At the same time, it actively evaluates measures related to water resource utilization. By making good use of water resources, it reduces the waste of water resources and improves the utilization rate of water resources. The main water used by SiRUBA head office is tap water supplied by the company, while the water used by the Taoyuan factory is tap water and groundwater. The water used by the Taoyuan factory is mainly used for cooling water tower evaporation and factory cleaning and rectification. Most of it is discharged through the sewage treatment system, and the raw water of the wastewater is regularly tested. And the discharged water, the remaining water is evaporated through the cooling water tower, and the clean water is directly discharged into the general ditch. The water used in the Gao Yin process is mainly used for product cleaning and is discharged after centralized treatment in the sewage treatment plant.

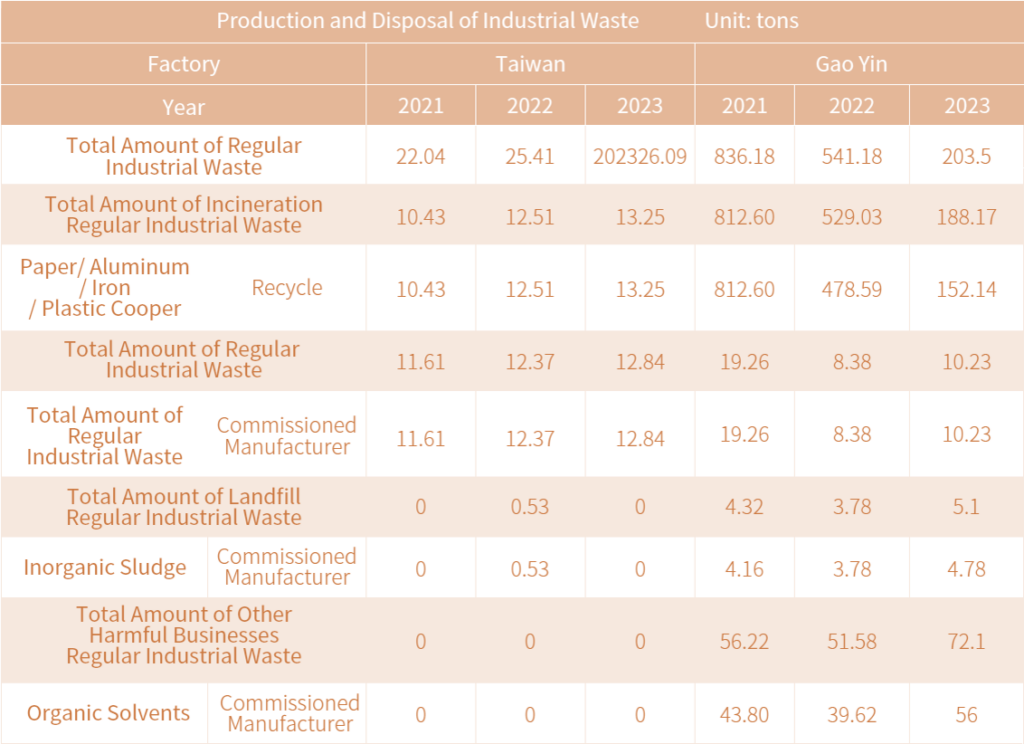

Waste Management

Being a sewing company, the primary types of industrial waste we generate include recycled paper, aluminum, iron, copper and plastic. Additionally, there are non-recyclable sewage materials that cannot be handled through incineration or landfill disposal. The hazardous waste category encompasses organic

solvents.

For industrial waste management, we entrust qualified waste removal and treatment firms to handle the waste removal and treatment at the site. We adhere to the stipulations of the Waste Disposal Law, which involves submitting a «Waste Disposal Plan» to the local environmental protection bureaus. Furthermore, we follow relevant regulations for reporting the production, temporary storage, and disposal of industrial waste.

Notably, our company has not incurred any environmental penalties from competent authorities for violation of environmental laws and regulations.

Regarding domestic waste, we actively engage in garbage classification and reduction. Qualified haulers are responsible for recycling and reusing these materials, contributing to our waste management practices.

Note: Life-waste could be different due to the statistical or not counted; industrial waste is based on the actual declared disposal amount. The total landfill volume in 2021 at the Gao Yin plant includes the volume of w aste lamps.